Optoelectronics

-

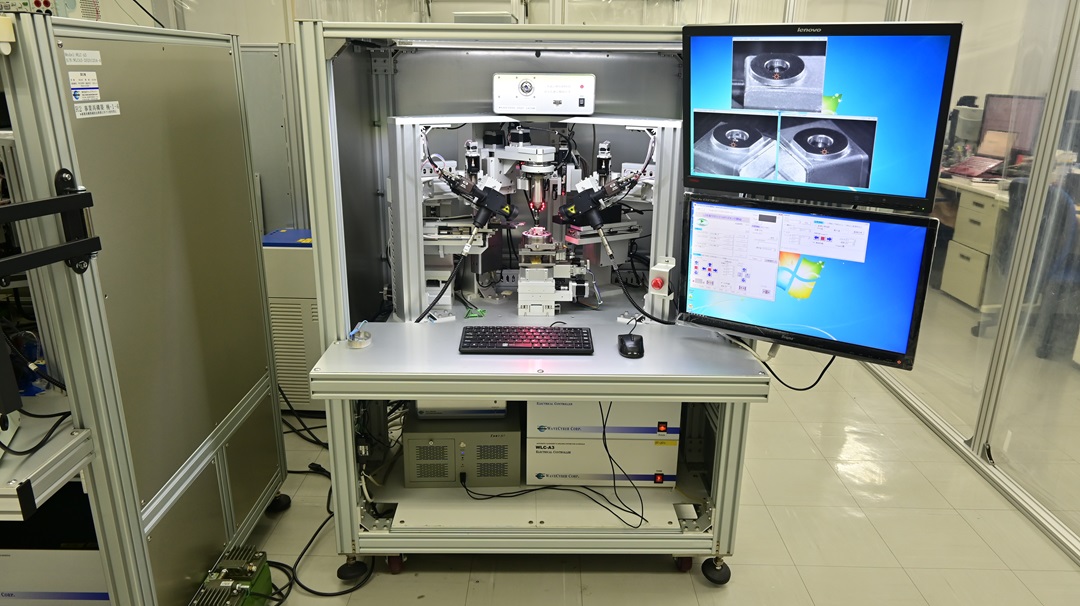

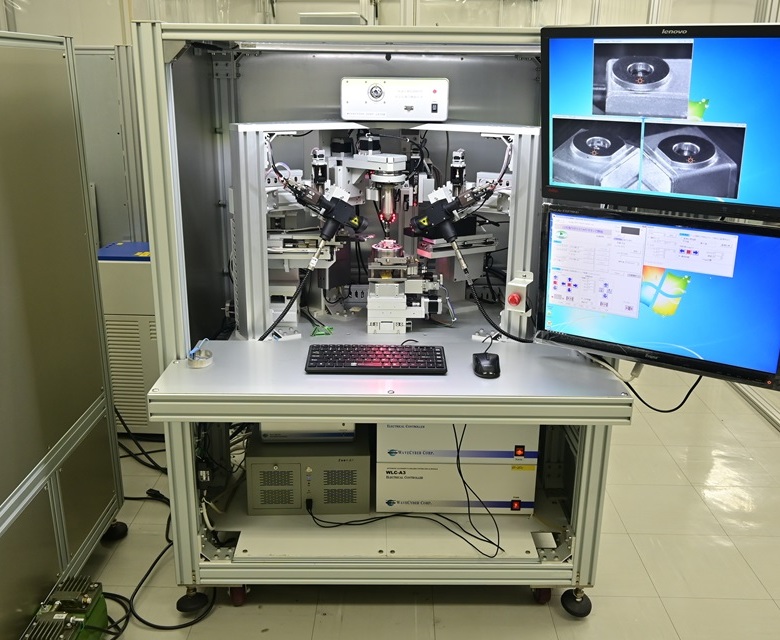

When the company was first founded, we were approached by an overseas manufacturer to develop a core alignment machine.The expertise of the founding members was well suited for this project, and they worked on the development and delivered the first machine within about six months.

During the several years of recession, business remained sluggish, although there were occasional orders.

In 2010, optical communication-related markets were revitalized as fiber-optic lines began to spread to ordinary homes.

The first machine had general performance, but this time, we incorporated our own technology to significantly improve alignment accuracy and speed, and delivered 15 units (@ 3 years) to the same manufacturer for mass production.

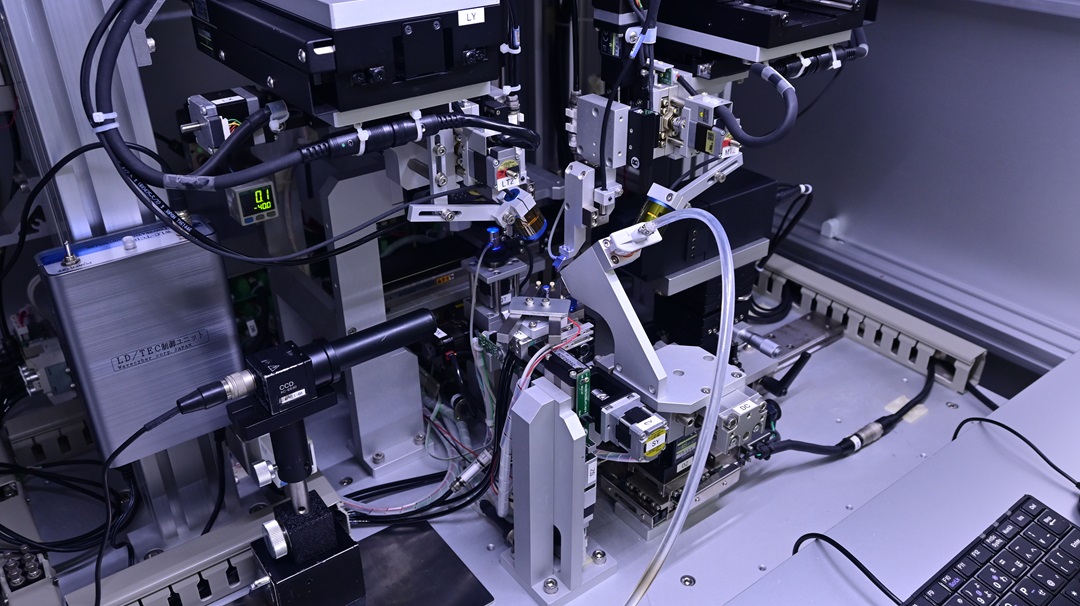

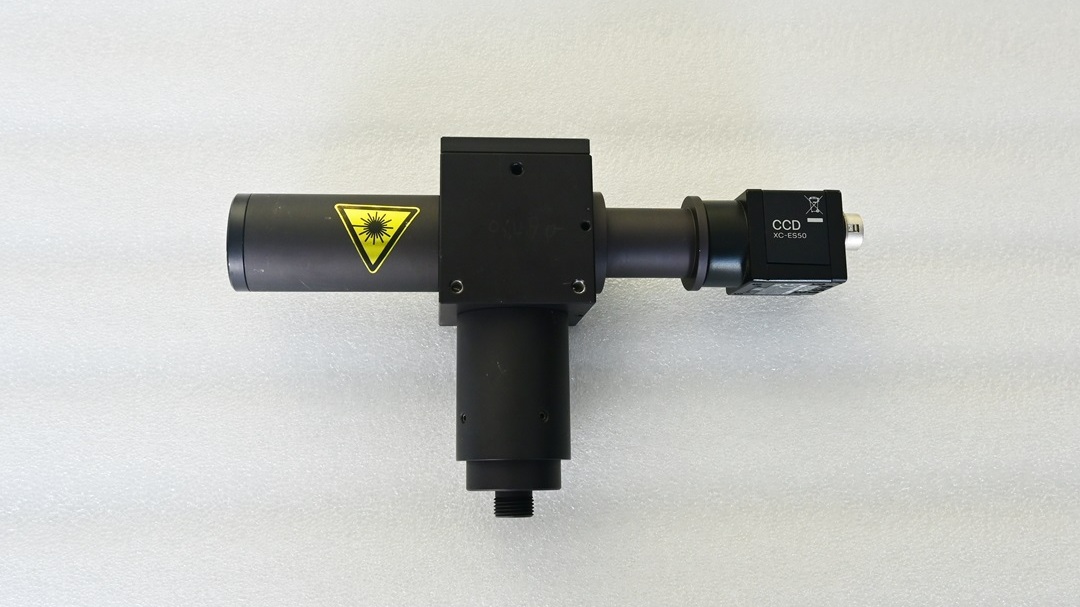

These achievements led to recognition by an overseas manufacturer, and we delivered 15 units to another manufacturer for mass production.Subsequently, we developed an optical beam observation unit (patented) as a technology to improve alignment accuracy and shorten takt time, and delivered multi-ch TOSA, multi-ch ROSA, and three body alignment machines with the features of our current alignment machines, which are used for mass production.

Furthermore, for mass production using multiple YAG welding process aligners, we have delivered a set of YAG laser switching devices that can distribute one welding laser to five YAG welding machines.

Currently, the machines are classified into two types according to the method of fixing optical components after centering: (1) YAG welding process centering machines and (2) UV process centering machines.

-

-

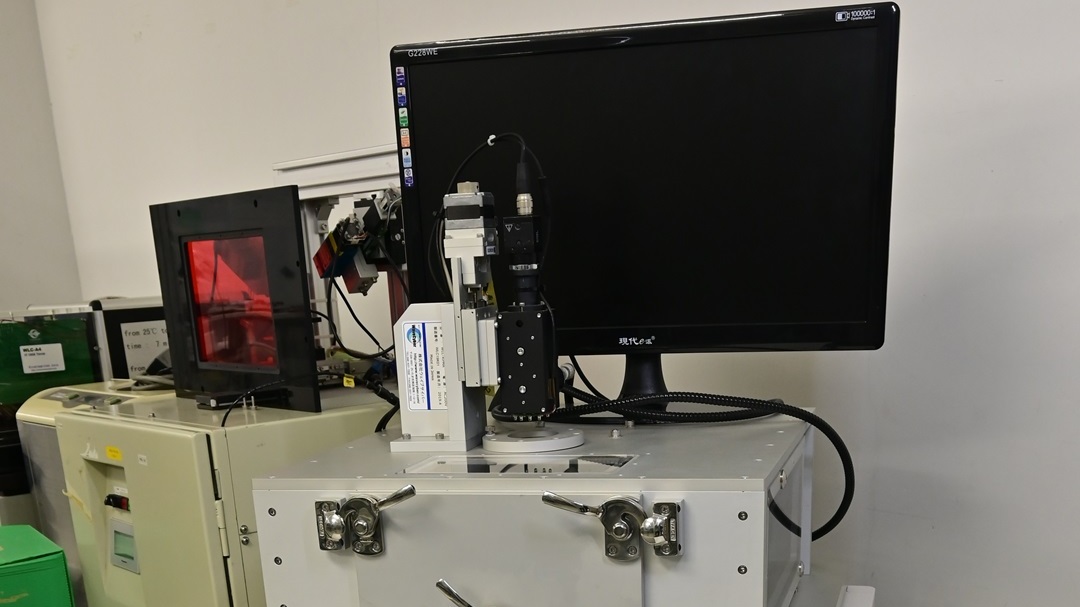

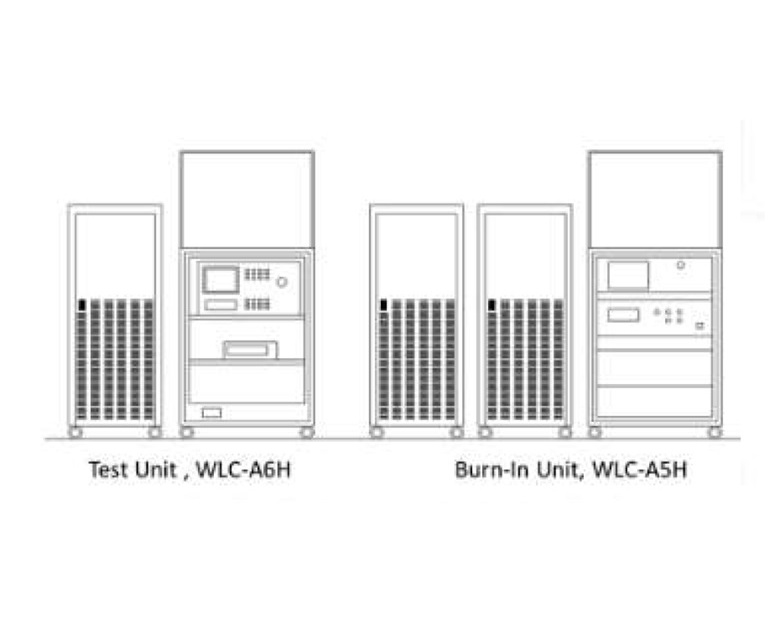

LD Temperature Characteristic Measuring Device

The unique light guide optics eliminates the need for a complicated alignment and aiming mechanism …VIEW MORE -

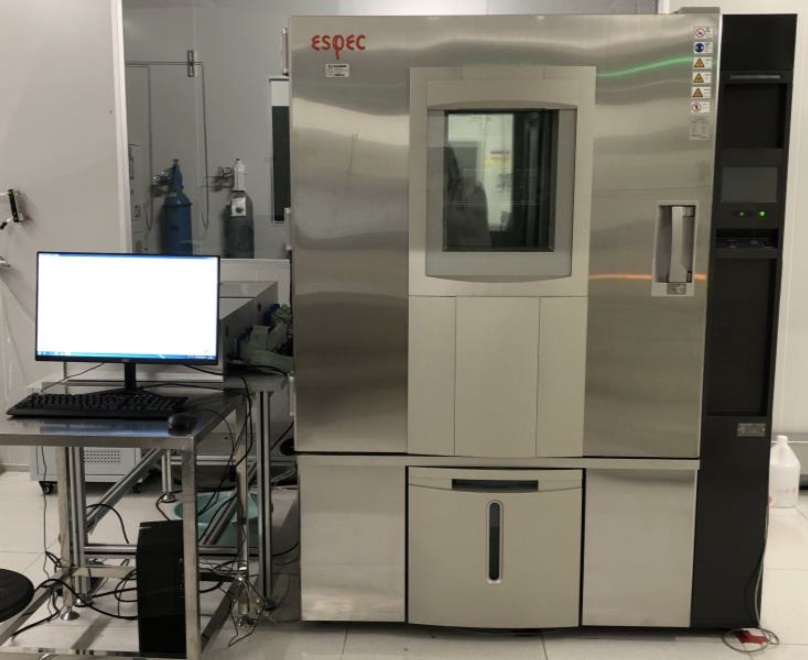

Constant temperature and humidity aging test equipment for LD module

It consists of a unit that charges optical chips in a constant temperature/humidity chamber at 85°C…VIEW MORE

-