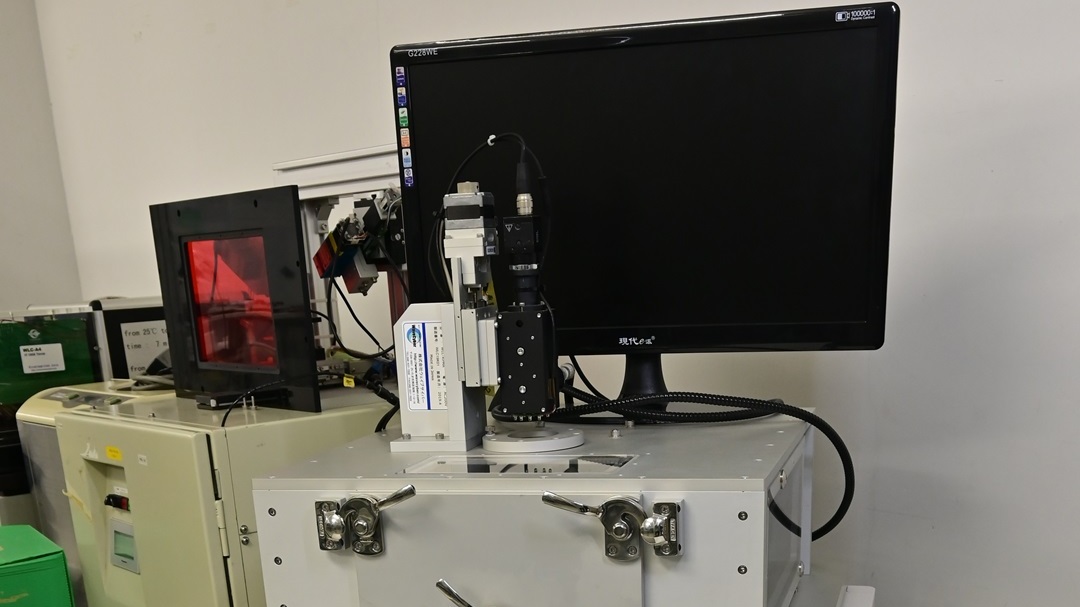

Optical Communication Module Sealing Device

Model name/ WLC-KPMA

Abstruct

Even for a combination of different size samples, the sealing process is performed automatically by image recognition.

Compared to the resistance welding method, the greatest features of this method are its excellent hermeticity and less influence of stress.

Since consumables are not generated, running costs can be very low.

Characteristicks

★ High-speed welding by YAG laser, beautiful finish

★ Less stress on the sample as seen in the conventional resistance welding method

* Because there is no pressure by the welding head

★ Pre-process: Sample body and lid are set on the dedicated tray.Pre-process: Sample body and lid are set in a special tray and the tray is installed in the equipment.

★ Reduced pressure and nitrogen environment (dew point control)

* Please provide your own nitrogen supply source.

Specifications

★ Lid welding part specification

Material: Nickel plated Kovar material

Thickness: around 0.1mm

★ Welding laser power variable

★ Equipment power supply voltage: 100V (not including laser equipment)

Applications

It has been adopted in the manufacturing process of BOX-type optical transmitter/receiver devices for optical communications and is now in operation as mass production equipment.