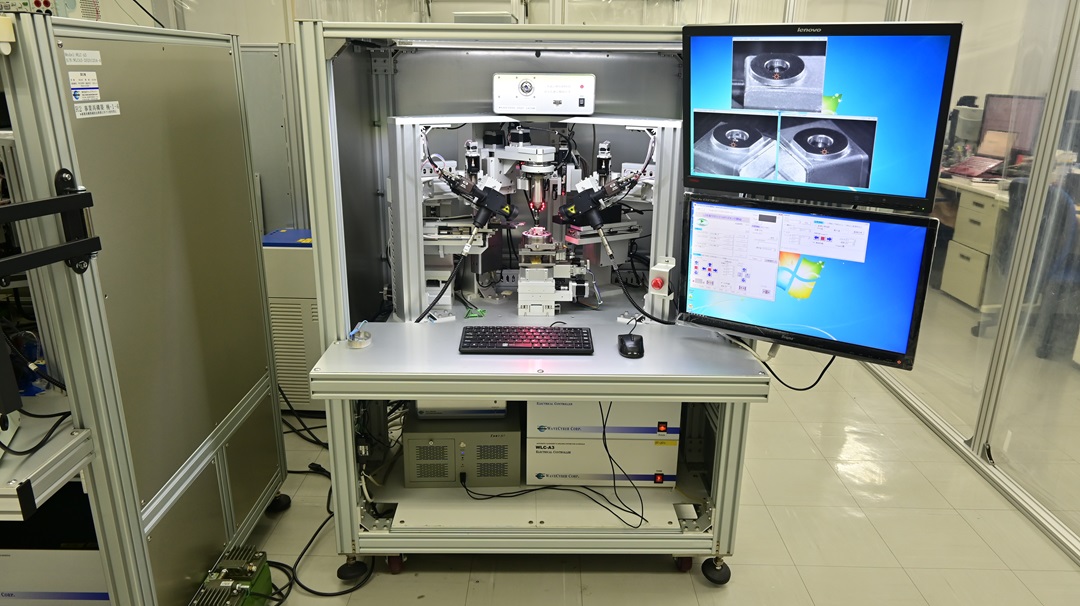

Alignment and YAG Welding Syste

The Alignment Solution for High-Precision, High-Efficiency Optical Device Welding.

The Alignment and YAG Welding System is a state-of-the-art alignment and welding station for high-precision YAG welding processes involving LD/PD modules, second lenses, and fiber receptacles. In addition to conventional 2-body alignment, this system fully supports complex 3-body alignment processes. By combining high-speed coarse alignment with a proprietary, patented beam observation unit, we deliver a solution that dramatically reduces tact time while achieving exceptionally stable, high-precision welding.

Key Advantages | Ideal for Addressing These Critical Challenges

This system is the optimal solution for manufacturers facing the following challenges:

- Stabilize the Quality of YAG Welding in the production of optical devices and pigtail modules.

- Handle Complex Multi-Core Devices that require high-precision, simultaneous 3-point alignment.

- Achieve High-Precision Alignment Without Relying on Skilled Operators, standardizing your production quality.

- Drastically Shorten Process Time and improve overall manufacturing tact time.

- Precisely Correct and Verify Laser Emitter Positions in advance of the welding process.

Features | Achieving Both Speed and Precision

-

Drastic Tact Time Reduction Significantly shortens the time required for initial alignment. A 1-point confirmation alignment can be completed in as little as 15 seconds, dramatically reducing overall tact time.

-

Full Support for Complex 3-Body Alignment Engineered to handle the alignment processes for complex assemblies, including LD/PD modules, second lenses, and fiber receptacles.

-

Achieve Optimal Coupling with Patented Technology Our patented beam observation unit allows for precise alignment of the collimated beam, optimizing the coupling efficiency. This ensures maximum performance and reliability of the finished optical device.

-

Advanced Polarization Extinction Ratio Alignment The system integrates an optical system capable of aligning based on the polarization extinction ratio, enabling high-precision alignment for advanced optical components.

Product Specifications

| Item | Specifications | |

|---|---|---|

| Alignment Device Specifications | LD focal point measurement | FL sensor unit (our original development) |

| YAG laser welding unit | Coaxial image processing optics with fine adjustment function | |

| Minute PW shift before and after welding (<10%) | ||

| Automatic aiming function (each CH has 2-axis automatic stage) | ||

| Alignment X-Y-Z stage | Stroke: 15 mm Minimum resolution: 0.1 μm | |

| Rotation Stage | Rotation range: 180 degrees | |

| Face Alignment Mechanism | Gimbal type automatic face alignment | |

| LD drive power supply | Supports up to 150 mA | |

| Power Sensor | InGaAs Photodiodes | |

| System Software | Application software for wireless LAN | |

| Functional Specifications | Adjustment method | Coarse and spiral fine adjustment by FL sensor unit, 1 point fixed time: approx. 15 sec. |

| Tact time (sec.) | 2P type: 40-50 3P type: 60-80 | |

| Power source | AC100, 200V | |

| External dimensions | 1100 x 1100 x 1400 (W x D x H1) excluding protrusions | |

| Weight | Approx. 300kg | |

Considering an Introduction?

Our Alignment and YAG Welding System is highly customizable and can be flexibly adapted for trial production and BCP measures. Please feel free to contact us for an initial consultation.